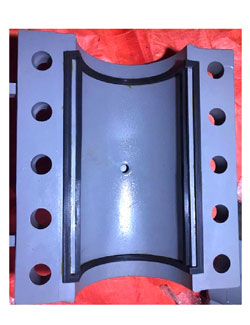

Emergency Repair Clamp

The TRITORC Split Sleeve Repair Clamp (SSRC Series) is an economical, bolt-together solution designed for both temporary and permanent pipeline repairs. Its two-half sleeves forms a high-integrity pressure vessel around damaged pipeline sections. Engineered for quick deployment, the SSRC clamp ensures safe and quick sealing performance. It also reduces downtime, making it an appropriate choice for emergency and planned pipeline maintenance.

Countries we serve in the Middle East

The TRITORC Split Sleeve Repair Clamp (SSRC Series) is an economical, bolt-together solution designed for both temporary and permanent pipeline repairs. Its two-half sleeves forms a high-integrity pressure vessel around damaged pipeline sections. Engineered for quick deployment, the SSRC clamp ensures safe and quick sealing performance. It also reduces downtime, making it an appropriate choice for emergency and planned pipeline maintenance.

Countries we serve in the Middle East

Overview

Repair clamps serve as a quick-response solution for utility providers facing unexpected service interruptions. When a pipeline experiences a crack, puncture, or minor damage, these clamps offer a temporary fix by sealing the affected area. They are suitable for use across various materials in both gas and water distribution networks.

These clamps are intended for short-term use to quickly restore functionality and minimize service downtime. A full-scale, permanent repair should follow to ensure long-term reliability of the system

These clamps are intended for short-term use to quickly restore functionality and minimize service downtime. A full-scale, permanent repair should follow to ensure long-term reliability of the system

Technical Specification

| Category | Specifications | |

|---|---|---|

| Sealing Mechanism | Premium elastomer seals compatible with pipeline product and operating temperature. Continuous pressure barrier formed by two circumferential and two longitudinal seals. Pre-compressed seal design for easy field replacement without factory repairs. | |

| Manufacturing Standards | Designed and tested per ASME Section VIII Division 1 & 2 specifications. Optional venting ports (½” or 1″) based on client requirements. | |

| Shell and Side Bar | ASTM A105, A106, A516, A216 Gr. WCB Casting or equivalent. | |

| Fasteners | ASTM A193 B7 / ASTM A194 2H with standard or PTFE coating. | |

| Seals | High-grade Nitrile Rubber (Buna N / Viton); special materials available on request. | |

| Coating | Topside Applications: Red Oxide coating. Subsea Applications: Marine-grade Yellow with cathodic protection via sacrificial anodes. | |

Frequently Asked Questions

What pipelines is it compatible with?

It works with pipelines carrying oil, gas, water, and other industrial fluids.