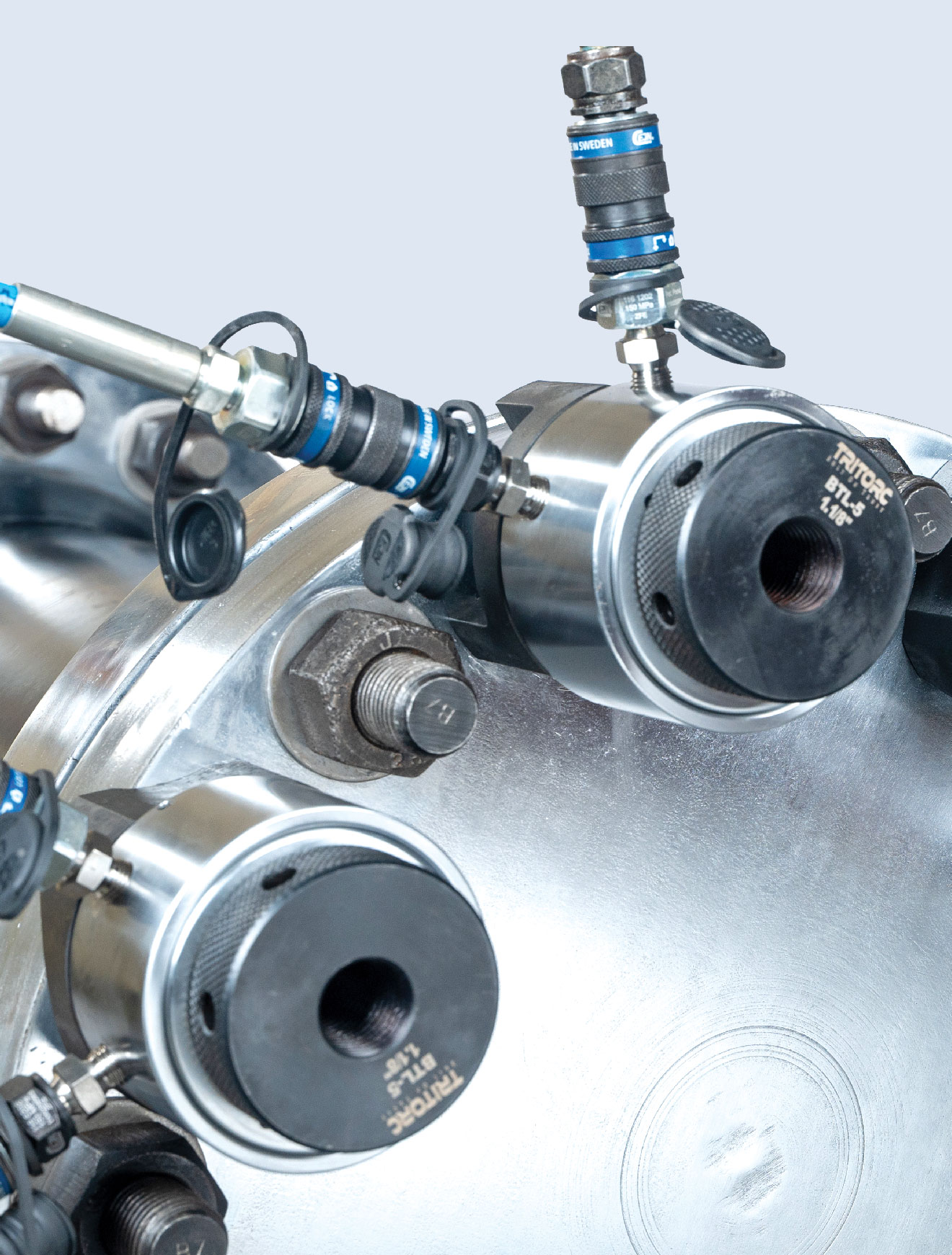

Top Side Hydraulic Bolt Tensioner – BTL Series

Overview

Technical Specification

| Model | Bolt Size | Cylinder | Hyd. Area | Dimension | Weight | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | ||||||

| Metric | Inch | kN(Ton) | cm2(in2) | mm(in) | mm(in) | mm(in) | mm(in) | mm(in) | mm(in) | kg(lbs) | |

| BTL-3 | M16 | – | 234.2 (23.88) | 15.7 (2.43) | 75 (2.95) | 32.5 (1.27) | 168 (6.61) | 90 (3.54) | 62 (2.44) | 47-51 (1.8-2.0) | 3 (6.61) |

| M18 | 3/4″ | ||||||||||

| M20 | – | ||||||||||

| M22 | 7/8″ | ||||||||||

| M24 | 1″ | ||||||||||

| BTL-5 | M27 | 1-1/8″ | 498.2 (50.80) | 33 (5.11) | 102 (4.01) | 47 (1.85) | 187 (7.36) | 106 (4.17) | 60 (2.36) | 65-71 (2.5-2.8) | 5.50 (12.12) |

| M30 | – | ||||||||||

| M33 | 1-1/4″ | ||||||||||

| M36 | 1-3/8″ | ||||||||||

| BTL-9 | M39 | 1-1/2″ | 896.8 (91.44) | 59.7 (9.25) | 133 (5.23) | 61 (2.40) | 208 (8.18) | 120 (4.72) | 60 (2.36) | 86-93 (3.4-3.7) | 10 (22.04) |

| M42 | 1-5/8″ | ||||||||||

| M45 | 1-3/4″ | ||||||||||

| M48 | 1-7/8″ | ||||||||||

| BTL-13 | M52 | 2″ | 1660.0 (169.27) | 83 (12.86) | 163 (6.41) | 73 (2.87) | 231 (9.09) | 135 (5.31) | 62 (2.44) | 106-114 (4.2-4.5) | 16 (35.27) |

| M56 | 2-1/4″ | ||||||||||

| M60 | – | ||||||||||

| BTL-19 | M64 | 2-1/2″ | 1843.3 (187.96) | 123 (19.06) | 193 (7.59) | 86.5 (3.40) | 254 (10) | 150 (5.90) | 62 (2.44) | 129-135 (5.1-5.3) | 22 (48.50) |

| M68 | – | ||||||||||

| M72 | 2-3/4″ | ||||||||||

| M76 | 3″ | ||||||||||

| BTL-27 | M76 | 3″ | 2640.5 (269.25) | 176 (27.28) | 233 (9.17) | 110 (4.33) | 286 (11.25) | 180 (7.08) | 73 (2.87) | 155-167 (6.1-6.6) | 40 (88.18) |

| M80 | – | ||||||||||

| M85 | 3-1/4″ | ||||||||||

| M90 | 3-1/2″ | ||||||||||

| M95 | 3-3/4″ | ||||||||||

| M100 | 4″ | ||||||||||

| BTL-37 | M90 | 3-1/2″ | 3768.0 (38.90) | 251 (384.22) | 280 (11.02) | 111-121 (4.4-4.8) | 304-338 (11.9-13.3) | 181-197 (7.1-7.7) | 37-40 (1.4-1.6) | 175-196 (6.9-7.7) | 64 (141.09) |

| M95 | 3-3/4″ | ||||||||||

| M100 | 4″ | ||||||||||

| M110 | 4.1-4″ | ||||||||||

| BTL-44 | M100 | 4″ | 4335.0 (442.04) | 289 (44.79) | 314 (12.4) | 121-140 (4.8-5.5) | 304-338 (11.8-13.3) | 181-197 (7.1-7.7) | 37-40 (1.4-1.5) | 210-233 (8.3-9.2) | 45 (99.20) |

| M110 | 4-1/4″ | ||||||||||

| BTL-54 | M120 | 4-3/4″ | 5407.0 (551.36) | 360 (55.80) | 344 (13.5) | 131-161 (5.1-6.3) | 354-388 (13.9-15.3) | 202-216 (7.9-8.5) | 42-47 (1.7-1.8) | 243-275 (9.5-10.8) | 73 (160.93) |

| M130 | 5-1/4″ | ||||||||||

| M140 | 5-1/2″ | ||||||||||

| M150 | 5-3/4″ | ||||||||||

Frequently Asked Questions

The BTL Series ensures precise and uniform tensioning, reducing the risk of uneven load distribution that can lead to bolt failures or joint leakage in critical industrial operations.